FIBERLY repurposes discarded cellulosic textiles into high-quality fibers that mimic the molecular architecture and function of natural cotton.

Benefits

- Low-impact, non-toxic, and fully traceable

- Provide strength, breathability, absorbency

Applications

- Textiles

UN Sustainable Development Goals Addressed

-

Goal 9: Industry Innovation & Infrastructure

-

Goal 12: Responsible Production & Consumption

-

Goal 13: Climate Action

The Challenge

Cotton, one of the most widely used materials in the $2.5 trillion fashion industry, is valued for its softness, breathability, and comfort. Yet, its production is tied to significant environmental and ethical issues, including heavy pesticide use, water stress, soil degradation, forced labor, and vulnerability to climate extremes like droughts and floods.

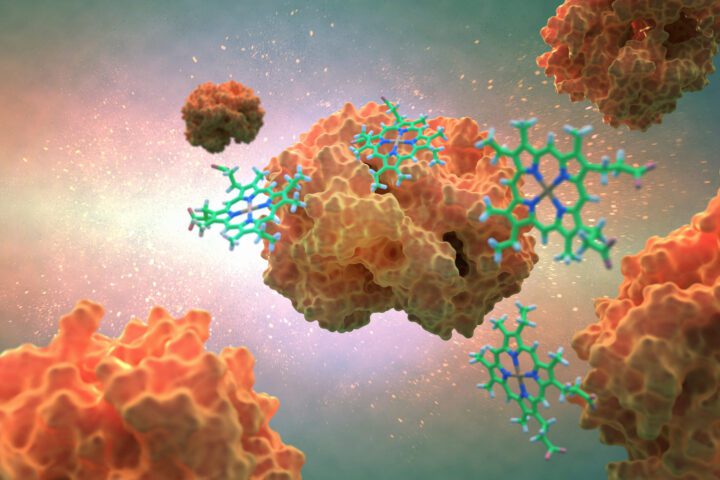

Biological Model

Natural cotton fibers, composed of nearly 100% , exhibit a unique architecture at both the macro and micro scales. On the macro scale, their twisted ribbon-like shape and flattened cross-section help fibers bind together, their high surface area increases absorbency, and their hollow cores provide flexibility. On the micro scale, the multilayer structure of cellulose microfibrils arranged in different orientations provides both strength and flexibility to the fiber, greatly influencing its mechanical performance.

Innovation Details

The team at FIBERLY is developing an innovative process to transform discarded textiles into high-quality fibers that replicate the molecular architecture of cotton, allowing them to behave like natural cotton in softness, breathability, absorbency, and hand feel. They have thoroughly studied the biological model of cotton fibers to re-engineer fiber production using discarded cellulosic textiles, a plant-based material found in many fabrics.

Their multistage process allows for precise control over the macro shape, surface aspect, and internal structure of the fibers. A precisely controlled regeneration phase influences how cellulose molecules align.

The system operates within a closed-loop process, where non-toxic solvents and water are recovered and reused, reducing environmental impact.

FIBERLY’s scalable approach provides a high-performance, lower-impact alternative to conventional cotton farming, positioning them at the forefront of textile innovation.

The Human Factor

The journey of FIBERLY began with a simple observation: cotton’s omnipresence in our wardrobes. From the intimacy of underwear to the ruggedness of sneakers, from cherished t-shirts and jeans to protective outerwear, cotton’s superiority is undeniable. Years of industry experience revealed a stark truth – despite technological advancements, no low-impact, high-quality alternative existed at scale. This realization ignited a mission: to replicate cotton’s remarkable properties without the environmental toll of cultivation. Inspired by cotton’s intricate natural architecture, the FIBERLY team embarked on an ambitious quest to re-engineer fiber production. Their innovative approach transforms discarded textiles into fibers that mirror cotton’s beloved characteristics, marking a significant step towards sustainable, high-performance textiles that honor nature’s ingenuity while preserving our planet’s resources.

Ray of Hope Accelerator

The Ray of Hope Accelerator supports an annual cohort of ten high-impact nature-inspired startups representing various sectors and regions addressing the world’s biggest environmental and sustainability challenges. The accelerator builds upon years of experience as the Ray of Hope Prize (2020-2023), which was created in honor of Ray C. Anderson, a business and sustainability leader and founder of Interface, Inc. FIBERLY was a participant in the 2024 Ray of Hope Accelerator.

AI on AskNature

This page was produced in part with the assistance of AI, which is allowing us to greatly expand the volume of content available on AskNature. All of the content has been reviewed for accuracy and appropriateness by human editors. To provide feedback or to get involved with the project, contact us.