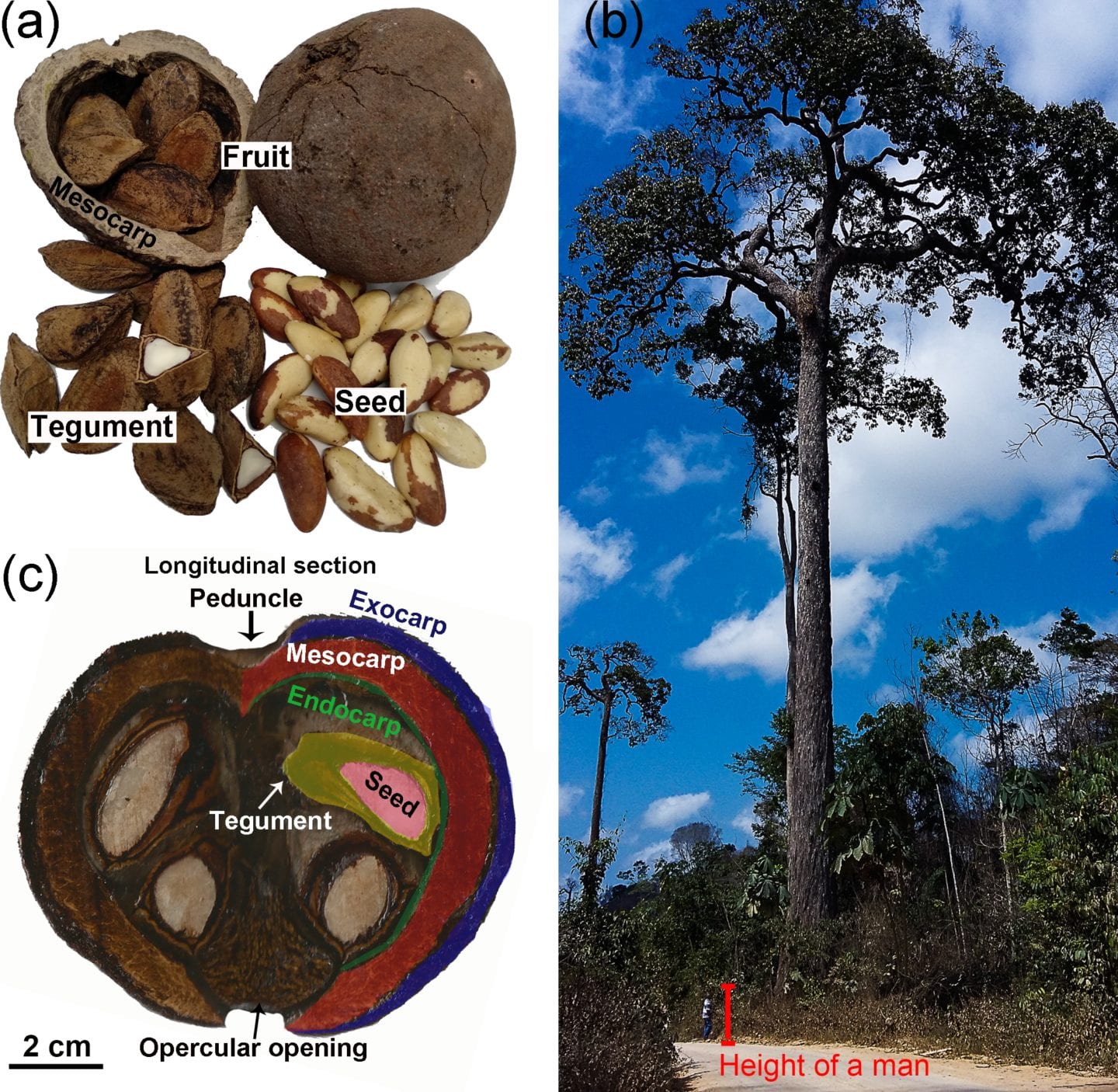

Brazil nut seed pods hurtle down from tall treetops, but their complex structure deters them from cracking open.

Introduction

People foraging for Brazil nuts in Amazon forests know they should always wear hard hats. The trees can reach 164 feet (50 meters) high. The nuts are encased in hard-shelled spherical pods roughly 6 inches (15 centimeters) in diameter that can weigh up to 5 pounds (2 kilograms). When those pods drop, they hurtle down like cannonballs at speeds of 50 miles per hour (80 kilometers per hour) and could easily smash your skull.

But the pods themselves don’t smash open. If they did, the nuts, or seeds, wouldn’t end up far from the parent tree. Brazil nut pods are built to ensure that they are dispersed by the one animal that can crack them open: the agouti. This guinea pig-like rodent has chisel-shaped teeth and muscular jaws. The pods are densely packed with up to two dozen nuts—more than an agouti can eat at once. So the provisioning critter will carry some away and bury them to eat later. The nuts the agoutis never come back for can take root and grow into trees.

That explains why Brazil nut pods are built so tough. But figuring out exactly how the pods can withstand such impacts has been a much harder nut to crack.

The Strategy

The secret to the pod shell’s impact resistance is a layer of material about half an inch (1 centimeter) thick, called the mesocarp. Only recently have scientists begun to take a microscopic look at this layer. Their research reveals that it is a multilayered amalgam of different-shaped cells and empty spaces—all arranged in a complex pattern that absorbs shocks and resists cracking.

The mesocarp contains two types of cells, both with thick walls made of lignin, a strong that gives plant stems their rigidity. First, there are elongated cells, organized like cables into strong, elastic fiber bundles. They are arranged in three layers. The two on the outside point in the same direction. Sandwiched in the middle is a bigger layer, oriented perpendicular to both.

Filling in most of the spaces between these bundles are spherical husks of dead cells called sclereids. Their centers are hollow, but their lignin walls are tough. This mesh of cells also has occasional voids—remnants of circulatory channels that transported water and nutrients to the fruit when it was growing. Using hollow or dead cells is a common strategy in nature that simultaneously helps optimize strength, stiffness, and weight.

When the pod smashes against the ground, the hollow sclereid cells compress, but don’t break apart. That absorbs a lot of shock, similar to the way foam does inside car bumpers.

The toughness of the lignin fibers resists cracking, but any cracks that do form in the outer layers stop when they hit the wall of perpendicular fibers in the middle layer.

The empty channels help in two ways. First, they provide spaces for cells to compress or slide into, dissipating some energy from impacts. Then, they offer paths of lesser resistance, directing energy along them and away from the fibers. Altogether, the mesocarp works to absorb energy from impact and create spiderweb-like networks of little tears that don’t converge into gaping cracks.

The Potential

Brazil nut pods offer an excellent model for fracture-resistant materials. Studying how the sizes, shapes, distribution, and orientation of cells in the mesocarp prevent cracking can inspire lightweight materials for transport containers, packaging, helmets and other protective gear, and devices to shield vehicles and buildings against impacts.