Nanofibers from Kiel University are made of cellulose from dried plant seed mucilage that gives them tunable friction characteristics.

Benefits

- Biodegradable

- Strong

- Biocompatible

Applications

- Medical implants

- Cosmetics

- Manufacturing

UN Sustainable Development Goals Addressed

-

Goal 3: Good Health & Wellbeing

-

Goal 9: Industry Innovation & Infrastructure

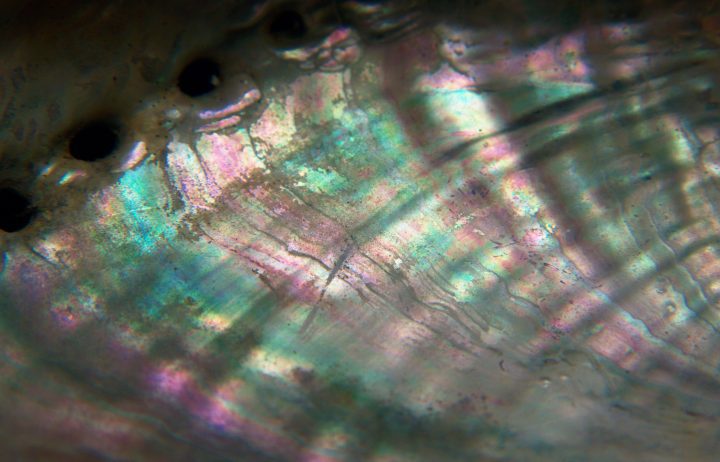

Bioutilization

- Mucilage

- Cellulose

The Challenge

Traditional nanofibers used in the medical, cosmetic, and food industries are made of carbon nanotubes. Although these carbon nanotubes work in these applications, their health effects have not yet been fully investigated.

Innovation Details

The nanofibers are made of nanofibrils derived from plant seed mucilage. The mucilage is dried using a gentle, critical-point methodology that does not harm the individual cell structures. The resulting nanofibers show strong dry friction and adhesive properties. Additionally, the nanofibers have electrical conductivity and are comparable in strength to their synthetic counterparts.

Biomimicry Story

Many plant seeds form a mucous sheath called a mucilage. One function of this coating is to help absorb and retain water, which enable seeds to create their own microenvironments suitable for germinating in arid environments. In addition, mucilage’s adhesive properties can help a germinating seed anchor to the ground or allow a seed to spread to new locations by sticking to the feathers of a bird or the fur of a migrating animal.