Mushroom Packaging from Ecovative Design uses mycelium to create a compostable, thermally insulating packaging.

Benefits

- Compostable

- Thermally insulating

- Reduced cost

- Nontoxic

Applications

- Standard and customizable commercial packaging

UN Sustainable Development Goals Addressed

-

Goal 9: Industry Innovation & Infrastructure

-

Goal 11: Sustainable Cities & Communities

-

Goal 12: Responsible Production & Consumption

Bioutilization

- Mycelium

- Cellulose

The Challenge

Common packaging materials, like styrofoam, do not degrade over time. They also introduce durable toxins to the environment that can harm wildlife and people.

Innovation Details

Mushroom Packaging® is a customizable packaging system made of mycelium, the vegetative part of a mushroom, and cellulosic agricultural byproducts, such as corn stalks, hemp hurds, and wood chips. Because mycelium can strongly bond materials together it is therefore an effective alternative for molded packaging.

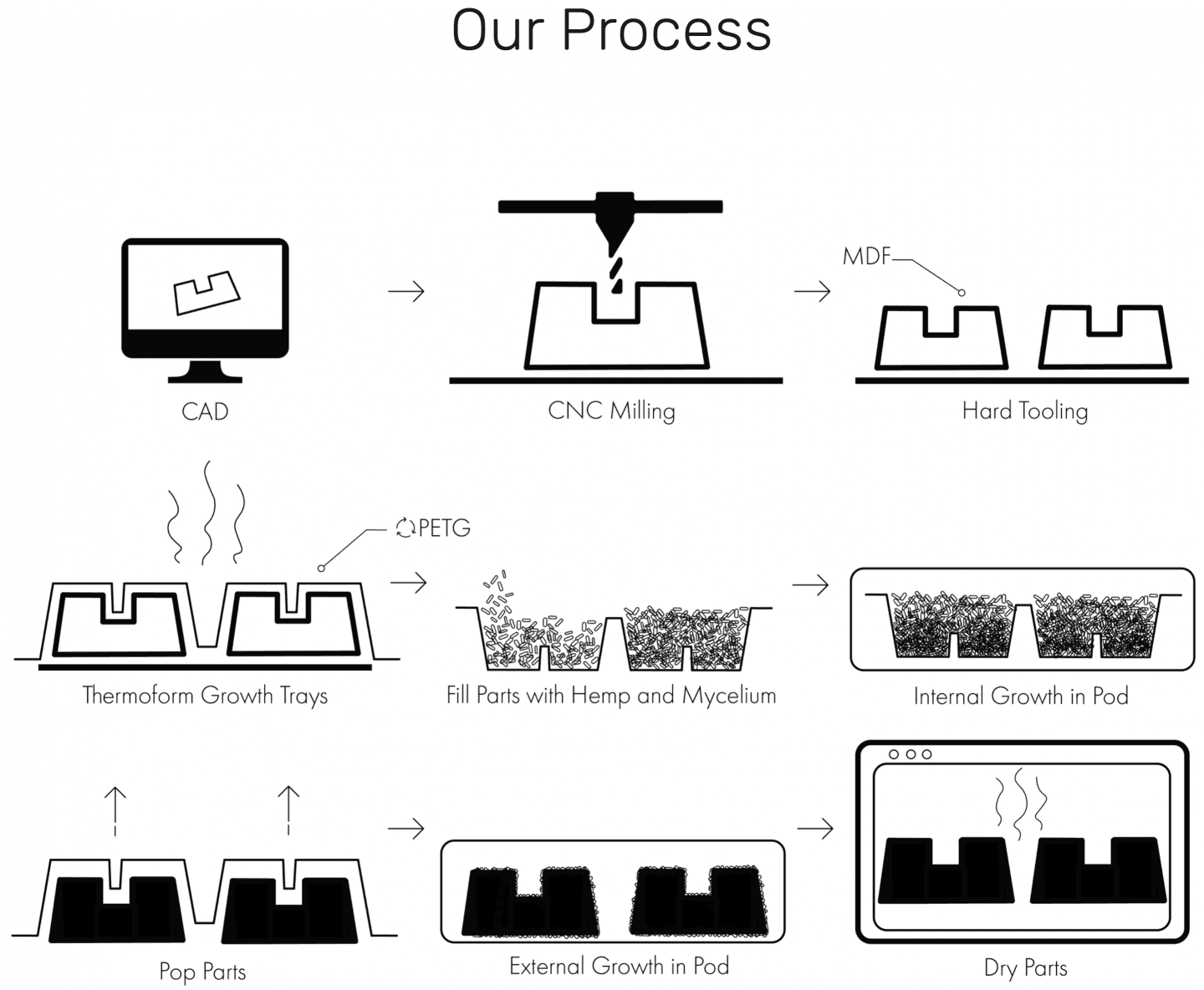

To produce Mushroom Packaging, mycelium is added to cellulosic material and placed into a mold. In a matter of days, the mycelium knits the substrate together into a solid mass. A drying process then halts mycelial growth. The dried and finished part that results is thermally insulating, water resistant, and fully home compostable.

Biological Model

Mushroom Packaging is an example of both and systems-level . Using biological materials in an innovative way has enabled Ecovative to create a system that mimics material cycling in nature, where natural “waste” material is transformed into a useful product that is fully biodegradable at the end of its life.