Actuator from Northern Arizona University has a coiled, helical structure that enables it to generate more power.

Benefits

- Flexible

- Adaptable

- Efficient

Applications

- Prosthetics

- Medical treatment

- Robotics

UN Sustainable Development Goals Addressed

-

Goal 3: Good Health & Wellbeing

-

Goal 9: Industry Innovation & Infrastructure

The Challenge

Pneumatic devices are used extensively in industrial and manufacturing processes. In certain applications, these actuators must be very large to provide sufficient strength. These actuators use a lot of energy and require continuous maintenance due to contamination.

Innovation Details

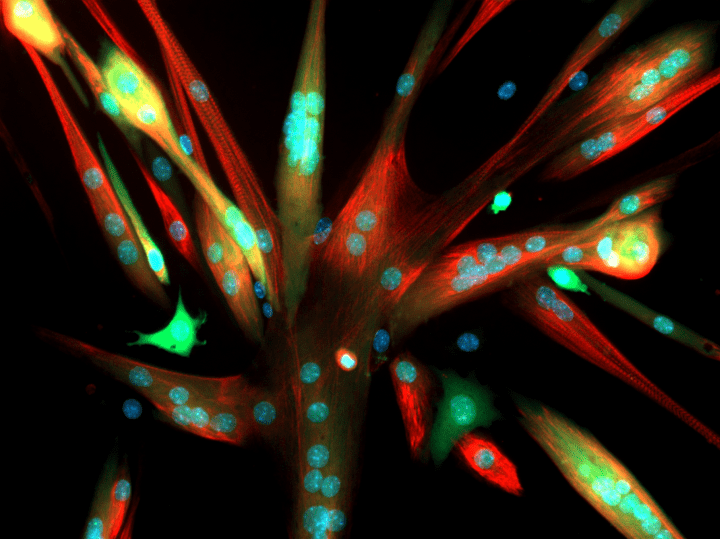

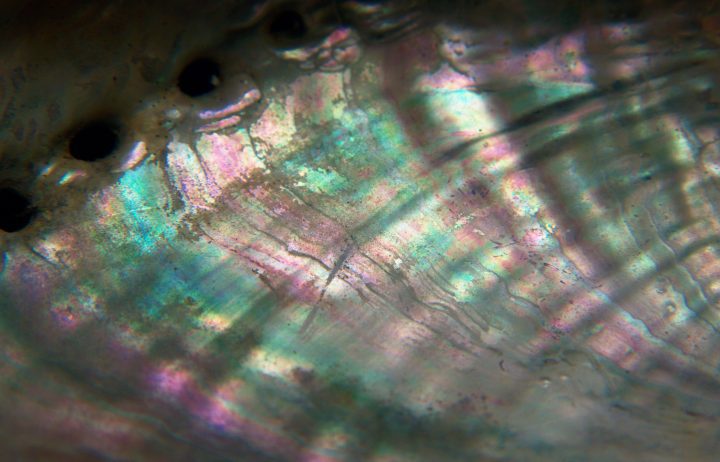

The actuator is fluid-driven and made of inexpensive tubes. The manufacturing of these tubes is the key to the performance of the actuator. The tubes are stretched and twisted, introducing anisotropy into their microstructure. When filled with hydraulic or pneumatic pressure within the actuator, the pressure inside the tubes results in a localized untwisting of the innate structure. This untwisting increases the potential energy of the system and enables the tubes to contract efficiently like a muscle.

Biomimicry Story

Muscles are essential for animal movement, and they are made up of thousands of small fibers. The fibers move in a specific sequence when the muscles flex, in order to deliver power and flexibility.