Nano-film from Tokyo University of Science uses a thin layer of glassy carbon to reduce reflection and adhesion.

Benefits

- Reduced light reflection

- Biodegradable

Applications

- Contact lenses

- Textiles

- Medical devices

- Solar energy

UN Sustainable Development Goals Addressed

-

Goal 12: Responsible Production & Consumption

The Challenge

Light reflection is a common problem that occurs in many applications. For example, any light that is reflected off solar panels reduces the total amount of energy that can be used, which decreases efficiency. Additionally, when particles such as dust adhere to a surface, they block potential light from entering, further reducing efficiency.

Innovation Details

The anti-reflective film consists of a thin layer of glassy carbon formed with a high-quality nanostructured mold. An inductively coupled plasma (ICP) system creates a mold to produce a transparent film with a nanostructure similar to those on the surface of a moth’s eye. The ICP system is able to make the mold at a larger scale, allowing the film to cover larger surfaces. The film’s reflectance toward light in the visible range is only 0.4%, ten times lower than that of a similar film without a moth-eye nanostructure. The transmittance of light through the material was also increased, meaning there was no trade-off in optical properties.

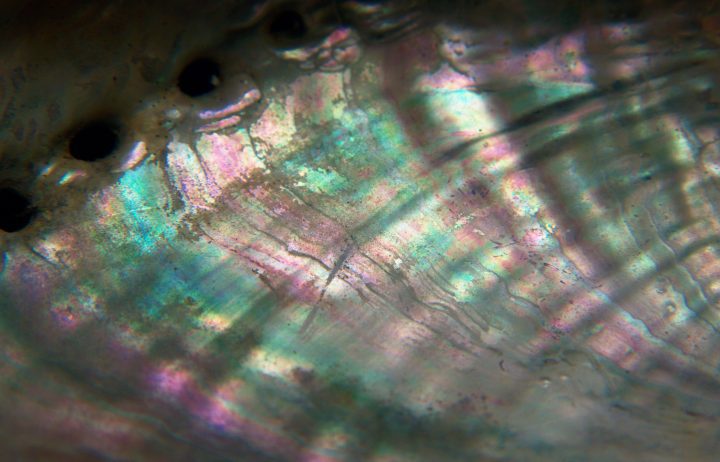

Biological Model

Moths hunt at dusk or at night when limited light is available. In order to maximize light capture, moth eyes are covered with a regular pattern of conical protuberances, generally 200-300 nm in height. These structures dramatically minimize light reflection over a broad range of wavelengths. This is because the protuberances are graded rather than polished, causing most of the incoming light to bend at the surface and be transmitted through the eye, rather than reflecting off it. These structures also help to create a barrier against dust and dirt.