The shafts of feathers and petioles of leaves protect from wind by having non-circular cross sections.

Introduction

Feathers, the quintessential feature of birds, are marvels of natural engineering tailored for flight. Each feather, especially the flight feathers of birds such as pigeons (Columba livia) and barn owls (Tyto alba), serves as a critical component in aerodynamics, providing lift, steering, and braking capabilities. Structurally, feathers are composed of a central shaft, or rachis, made primarily of keratin, a also found in human hair and nails. The rachis has evolved a shape and flexibility to withstand the varying forces experienced during flight. This not only maximizes aerodynamic efficiency but also ensures the feather’s durability against potential structural failures.

The Strategy

The rachis of a feather is a masterpiece of biomechanical design, optimized to manage the stresses and strains of flight. Its cross-sectional geometry is a key to its functionality. In plants, a petiole supports the leaf and absorbs the downward bending caused by its weight, while in birds, the feather rachis endures upward bending due to aerodynamic loading. This structural alignment allows the rachis to handle significant tension without buckling, a principle evident in the feather’s ability to sustain more compressive strain during the downstroke of a wingbeat compared to tensile strain during the upstroke.

Scientific studies have demonstrated that the feather rachis withstands these dynamic stresses well within its material capabilities, exhibiting a high safety factor The precise arrangement of keratin fibers and the specialized design of the rachis contribute to this, allowing the feather to flex under pressure and return to its original shape, a process critical for efficient and repetitive wing movements.

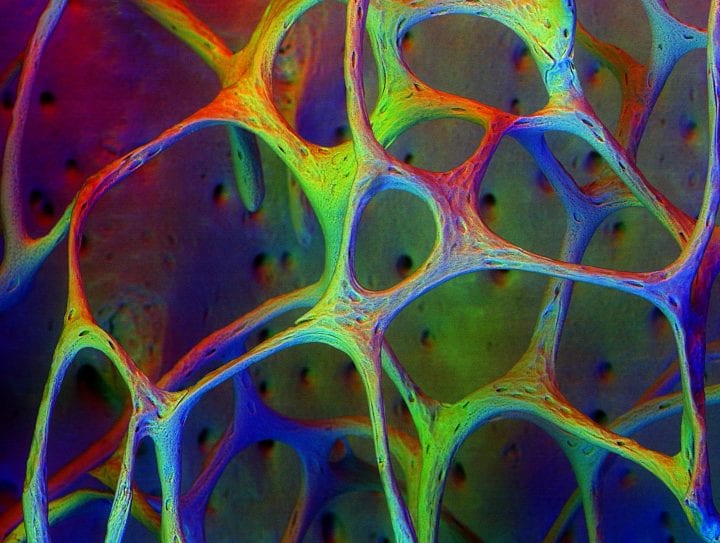

The configuration of the rachis varies between species, adapted to their specific flight needs. For instance, barn owls, which generally fly slower and with more maneuverability, have feathers with a higher second moment of area, which means the feather is stiffer and more resistant to bending forces. This structural stiffness is primarily influenced by the geometry of the feather rather than the material properties of the keratin. A key feature that contributes to this increased stiffness is the presence of a groove along the rachis. This groove, running along the length of the feather shaft, effectively distributes the material in such a way that it enhances the feather’s resistance to bending. The groove creates a sort of “I-beam” structure, similar to those used in engineering for their high strength-to-weight ratio. By placing more material away from the central axis of the rachis, the groove increases the second moment of area, making the feather more rigid and capable of withstanding the stresses encountered during flight.

The Potential

The biomechanical principles found in bird feathers, particularly their ability to maintain structural integrity under varying loads, offer valuable insights for human design, especially in aerospace and architectural engineering. By emulating the grooved, tension-optimized structure of the feather rachis, engineers can develop more efficient and resilient materials and structures. For instance, designing aircraft wings that mimic the rachis’s geometry to handle different types of strains could lead to improvements in fuel efficiency and safety.

Furthermore, the natural safety factor observed in feathers suggests a model for building more robust yet lightweight materials. Structures made with a high safety factor can withstand unexpected stresses, making them ideal for unpredictable environments. Additionally, utilizing a synthetic keratin-analogue points towards innovative approaches in material science, focusing on potentially biodegradable and eco-friendly alternatives to conventional synthetic materials.

In architecture, the principles of flexibility and resilience observed in feather design could influence the construction of buildings that better withstand natural forces, such as earthquakes or high winds. By integrating design and material strategies inspired by the feather rachis, human-made structures could not only become more adaptive and resilient but also potentially more sustainable throughout the life cycle of their materials.

AI on AskNature

This page was produced in part with the assistance of AI, which is allowing us to greatly expand the volume of content available on AskNature. All of the content has been reviewed for accuracy and appropriateness by human editors. To provide feedback or to get involved with the project, contact us.