Stems of scouring horsetail vary their stiffness by having rings of supportive tissues that react to changes in turgor.

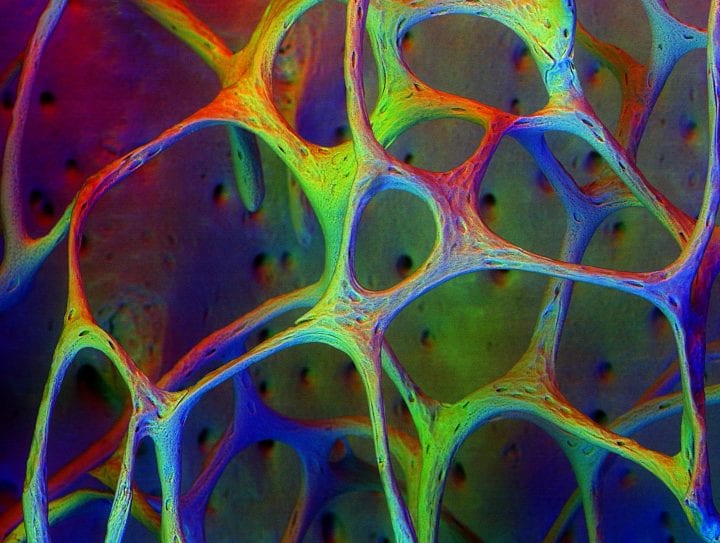

“Plants with hollow axes, e.g. various horsetails and grasses, serve as

generators of biological concepts for technical structures with

variable stiffness. Their structure is characterised by a thin outer

ring of strengthening tissue stabilised by a lining of parenchyma cells

(Fig. 1A-C). The hollow stems are divided into shorter segments

(internodes) by transverse walls and stem thickenings at the so called

nodes. The nodes significantly reduce the danger of local buckling in

these light-weight structures. The stability of these stems depends

significantly on the internal pressure (turgor) of the parenchymatous

cells. If the turgor pressure is reduced, e.g. by water deficiency,

stiffness and stability of the stems decrease. In some species–such as

the Brazilian Giant Horsetail (Equisetum giganteum)…the resistance to

ovalisation is extremely turgor-dependent. In other horsetail

species–such as the Dutch Rush (E. hyemale)–the outer ring of

strengthening tissue is connected via wedge-shaped elements with an

inner ring of strengthening tissue forming a mechanically resistant

sandwich structure (Fig. 1D, E). These stems are also stabilised by the

pressurised lining of parenchymatous cells but depend much less on the

turgor pressure of the parenchyma cells. The mechanical stability

resisting stem ovalisation is diminished by only about 20% due to

reduction of the turgor pressure.

“Potential technical

implementations are manifold, inspired by plants with mechanical

properties of the stem varying with the internal pressure of the

pressurised cellular lining. These include light-weight structures with

chambered pressure-stabilised pneumatic structures that feature a

segmental variation of stiffness and the ability to adapt their

stiffness or form to changing outer conditions, facilitated either

adaptively or via integrated active control. Envisaged technical

applications for these types of biomimetic technical smart materials

include: (1) shells of airplane wings and other aircraft (adaptation to

changing aerodynamics); (2) shells of buildings of innovative

construction; (3) car parts, e.g. aerodynamically adjustable spoilers.”(Speck et al. 2004:199-200)